Mercedes Benz S Class vehicles are known for their luxurious features and smooth driving experience. However, like any other vehicle, they can experience transmission issues. One common problem that affects these vehicles is related to the transmission valve body and conductor plate. In this guide, we will delve into the details of Mercedes Benz S Class transmission valve body and conductor plate problems, helping you understand the causes, symptoms, and potential solutions.

Introduction to Mercedes Benz S Class Transmission Valve Body and Conductor Plate Problems

In this section, we will provide a brief overview of Mercedes-Benz S Class transmission problems, focusing on the valve body and conductor plate issues. These components play a crucial role in the smooth operation of the transmission system, and any malfunction can lead to performance issues and costly repairs.

Defining the role of the transmission valve body in Mercedes-Benz vehicles

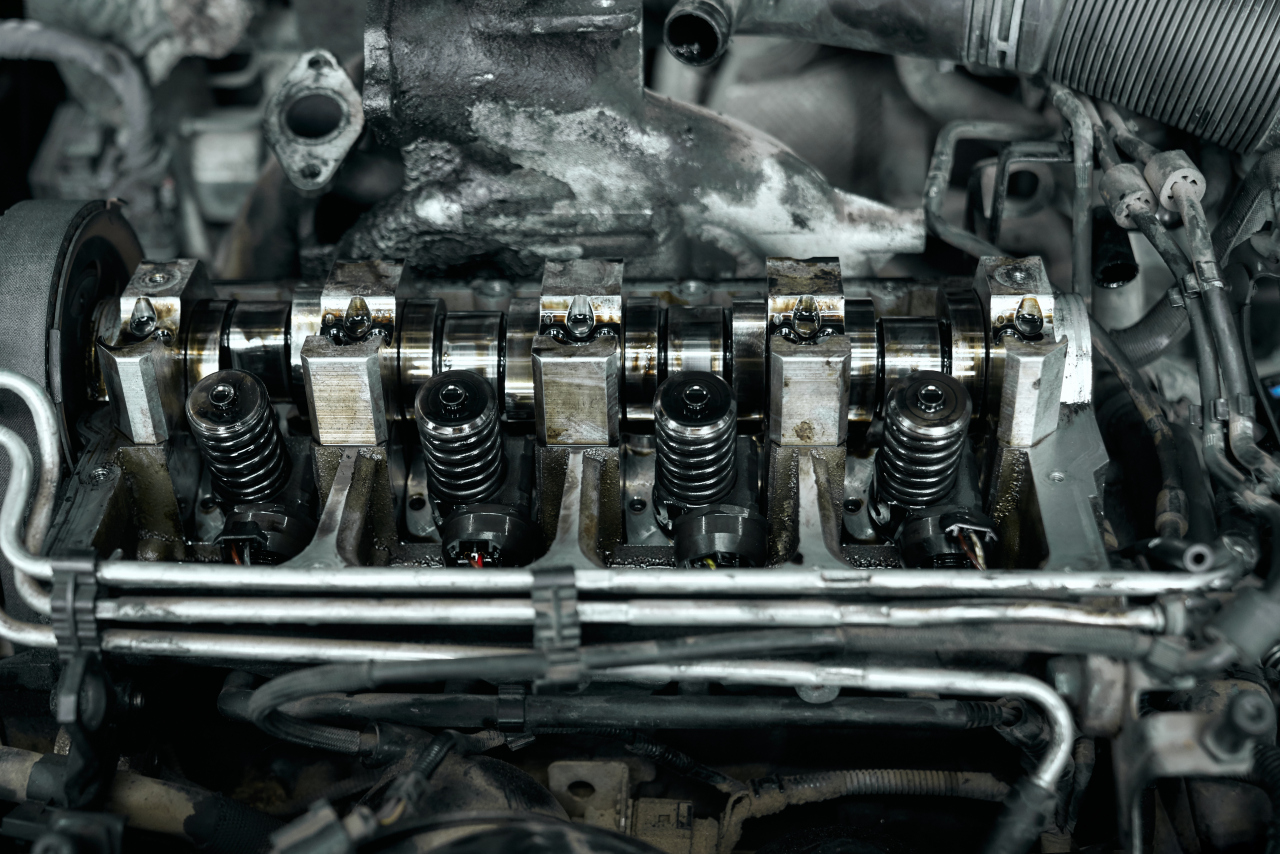

The valve body is a critical component of an automatic transmission system. It functions as the “brain” of the transmission, directing the flow of hydraulic fluid to engage the appropriate gear based on the driver’s input. The valve body contains a complex network of channels, valves, and solenoids that work together to ensure smooth gear shifts and optimal performance.

However, valve body issues can arise in Mercedes-Benz vehicles, leading to erratic shifting, delayed gear engagement, and even transmission failure. Common problems include wear and tear of internal components, solenoid malfunctions, and issues with the electronic control unit (ECU) that manages the valve body’s operation.

Understanding the function of the conductor plate in Mercedes 722.9 transmission

The conductor plate, also known as the “merc benz conductor plate,” is an essential component of the Mercedes 722.9 transmission, which is commonly found in S Class vehicles. This plate serves as an interface between the transmission’s mechanical components and its electronic control system. It houses various sensors and solenoids that relay information to the ECU, allowing it to make real-time adjustments to the transmission’s operation.

Unfortunately, conductor plate problems can occur in the Mercedes 722.9 transmission, leading to a range of symptoms such as harsh gear shifts, slipping, and even complete loss of drive. Common issues include damaged sensors, faulty solenoids, and electrical problems within the conductor plate itself.

In the following sections, we will delve deeper into the specific conductor plate and valve body problems that affect Mercedes-Benz S Class vehicles, as well as discuss potential solutions and repair options.

Common Conductor Plate Problems in Mercedes-Benz S Class

In this section, we will discuss the conductor plate problems commonly encountered in Mercedes-Benz S Class vehicles. We will also explain the impact of these problems on the vehicle’s performance and how they can lead to transmission issues.

Identifying signs of a failing plate in Mercedes 7G-Tronic automatic transmissions

A failing plate in a Mercedes 7G-Tronic automatic transmission can manifest in various symptoms. Some of the most common signs indicating a potential conductor plate issue include:

- Erratic or harsh gear shifts

- Slipping between gears

- Delayed gear engagement

- Transmission going into limp mode

- Check engine or transmission warning lights

- Diagnostic trouble codes related to transmission sensors or solenoids

These symptoms can significantly affect the vehicle’s performance and, if left unaddressed, may lead to more severe transmission damage.

How solenoids contribute to conductor plate issues

Solenoids play a crucial role in the operation of the conductor plate, as they control the flow of hydraulic fluid within the transmission system. They are responsible for activating the appropriate gear based on the driver’s input and the vehicle’s speed. However, solenoids can contribute to conductor plate issues in several ways:

- Wear and tear of solenoid components, leading to erratic operation

- Electrical issues, such as short circuits or open circuits, affecting solenoid function

- Contamination of hydraulic fluid, causing solenoid blockages

When solenoids malfunction, they can cause a range of conductor plate problems, including erratic gear shifts, slipping, and transmission faults.

The impact of transmission faults on the conductor plate

A transmission fault can have a significant impact on the conductor plate, as it can cause the plate to malfunction or fail altogether. Some of the ways transmission faults can affect the conductor plate include:

- Excessive heat generated by the transmission, leading to damage of the conductor plate’s electronic components

- Contamination of hydraulic fluid, causing blockages in the conductor plate’s channels and solenoids

- Wear and tear of mechanical components, resulting in debris that can damage the conductor plate

Understanding the relationship between transmission faults and conductor plate issues is essential for diagnosing and addressing these problems in Mercedes-Benz S Class vehicles.

Valve Body Issues in Mercedes-Benz S Class

In this section, we will explore the common valve body issues in Mercedes-Benz S Class vehicles and discuss their impact on the vehicle’s performance. Valve body issues can lead to transmission problems, affecting the overall driving experience.

The role of hydraulic pressure in valve body problems

Hydraulic pressure plays a crucial role in the operation of the transmission valve body, as it controls the flow of hydraulic fluid within the transmission system. Maintaining proper hydraulic pressure is essential for the smooth functioning of the valve body. However, hydraulic pressure can contribute to valve body problems in several ways:

- Low hydraulic pressure, leading to insufficient fluid flow and poor gear engagement

- High hydraulic pressure, causing excessive wear and tear on the valve body components

- Fluctuating hydraulic pressure, resulting in erratic gear shifts and transmission performance

Understanding the importance of maintaining proper hydraulic pressure can help prevent valve body issues and ensure optimal transmission performance.

Understanding the gearbox code related to valve body issues

Gearbox codes are essential diagnostic tools that can help identify valve body issues in Mercedes-Benz S Class vehicles. These codes provide information about the specific problem affecting the valve body and can guide technicians in diagnosing and repairing the issue. Some common gearbox codes related to valve body issues include:

- P0730: Incorrect gear ratio

- P0715: Input/turbine speed sensor malfunction

- P0720: Output speed sensor malfunction

- P0753: Shift solenoid A malfunction

Interpreting these codes can help pinpoint the exact cause of the valve body issue and facilitate a more efficient repair process.

How electronic control contributes to valve body issues in 5G-Tronic 722.6 transmissions

Electronic control plays a significant role in the operation of the valve body, particularly in 5G-Tronic 722.6 transmissions found in some Mercedes-Benz S Class vehicles. The electronic control unit (ECU) manages the transmission’s shifting patterns and overall performance. However, electronic control can contribute to valve body issues in several ways:

- Software glitches or outdated firmware, leading to incorrect shifting patterns

- Electrical issues, such as short circuits or open circuits, affecting the ECU’s communication with the valve body

- Malfunctioning sensors or solenoids, causing incorrect data input to the ECU and resulting in poor transmission performance

Addressing electronic control issues in 5G-Tronic 722.6 transmissions can help prevent valve body problems and ensure optimal transmission performance in Mercedes-Benz S Class vehicles.

Solutions and Repairs for Mercedes-Benz S Class Transmission Problems

In this section, we will discuss common solutions and repairs for transmission problems in Mercedes-Benz S Class vehicles. We will also emphasize the importance of seeking professional repair services to ensure the longevity and performance of your vehicle’s transmission system.

When to consider a TCM replacement for your Mercedes-Benz

A TCM replacement might be necessary when the transmission control module (TCM) in your Mercedes-Benz S Class is malfunctioning or has failed. The TCM is responsible for managing the transmission’s shifting patterns and overall performance. Some signs that a TCM replacement may be needed include:

- Erratic or harsh shifting

- Transmission slipping or delayed engagement

- Transmission going into limp mode

- Diagnostic trouble codes related to the TCM

Replacing the TCM involves removing the old module and installing a new one, followed by programming it to communicate with the vehicle’s other control modules. This process should be performed by a professional technician to ensure proper installation and functionality.

Exploring the availability of replacement parts for Mercedes-Benz S Class transmissions

When it comes to replacement parts for Mercedes-Benz S Class transmissions, it is crucial to use high-quality components to ensure optimal performance and longevity. Some available replacement parts include:

- Conductor plates

- Valve bodies

- Solenoids

- Transmission control modules

- Seals and gaskets

Using quality replacement parts not only ensures proper fit and function but also helps prevent future transmission problems and costly repairs.

The benefits of test & repair service for Mercedes-Benz transmission problems

A test & repair service can be highly beneficial in diagnosing and fixing transmission problems in Mercedes-Benz S Class vehicles. These services involve a thorough inspection of the transmission system, including:

- Checking for diagnostic trouble codes

- Inspecting fluid levels and condition

- Examining the valve body and conductor plate for damage or wear

- Testing solenoids and sensors for proper function

By identifying the root cause of the transmission problem, test & repair services can help ensure that the appropriate repairs are made, preventing further damage and prolonging the life of your vehicle’s transmission.

Understanding the use of re-man parts in Mercedes-Benz transmission repairs

Re-man parts, or remanufactured parts, are components that have been restored to like-new condition through a rigorous process of disassembly, cleaning, inspection, and replacement of worn or damaged parts. Using re-man parts in transmission repairs can offer several benefits, such as:

- Cost savings compared to new parts

- Reduced environmental impact due to recycling and reusing materials

- Quality assurance through thorough testing and inspection

However, there can be some drawbacks to using re-man parts, such as limited availability or potential compatibility issues. It is essential to weigh the benefits and drawbacks of using re-man parts and consult with a professional technician to determine the best course of action for your Mercedes-Benz S Class transmission repairs.